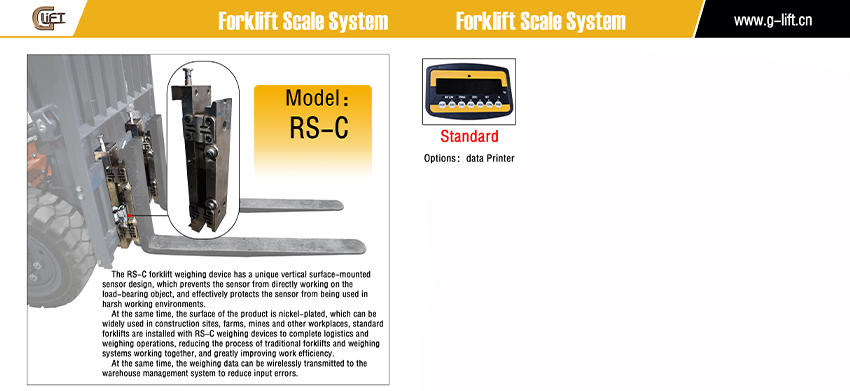

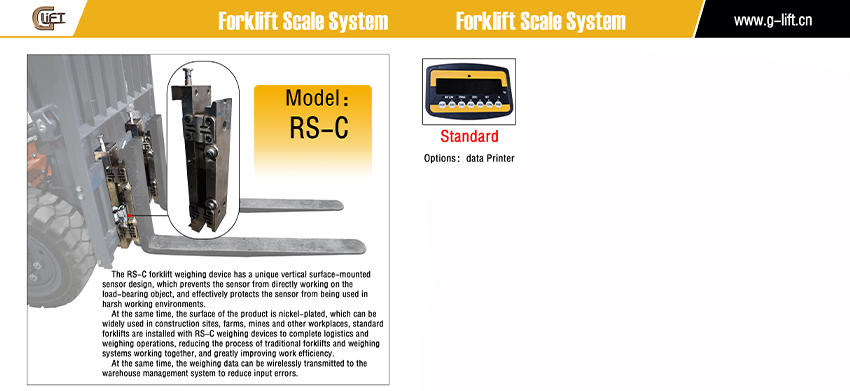

The RS-C forklit weighing device has a unique vertical surface-mounted sensor design, which prevents the sensor from directly working on the load- bearing object, and effectively protects the sensor from being used in harsh working environments. At the same time, the surface of the product is nickel-plated, which can be widely used in construction sites, farms, mines and other workplaces, standard forkifts are installed with RS -C weighing devices to complete logistics and weighing operations, reducing the process of traditional forklifts and weighing systems working together, and greatly improving work efficiency. At the same time, the weighing data can be wirelessly transmitted to the warehouse management system to reduce input errors.

RS-C, Wireless weight sensor system for forklift trucks, require a fixed sensor installation on the forklift truck and lock with original forks come with

the trucks. The sensor is located on the vertical direction of the fork to prevent damage from impact and ingress protection 65 which is suitable for outdoor use. A rS-C system consists by two separate units, each powered by its own lithium battery unit.

Advantages:

Use with multifunction indicators or wireless handheld terminal

The RS-C forkift scale system can be used with multifunction indicators for weighting, dosing, accumulation or piece counting and can be also used with wireless handheld terminal for additional functionality you need.

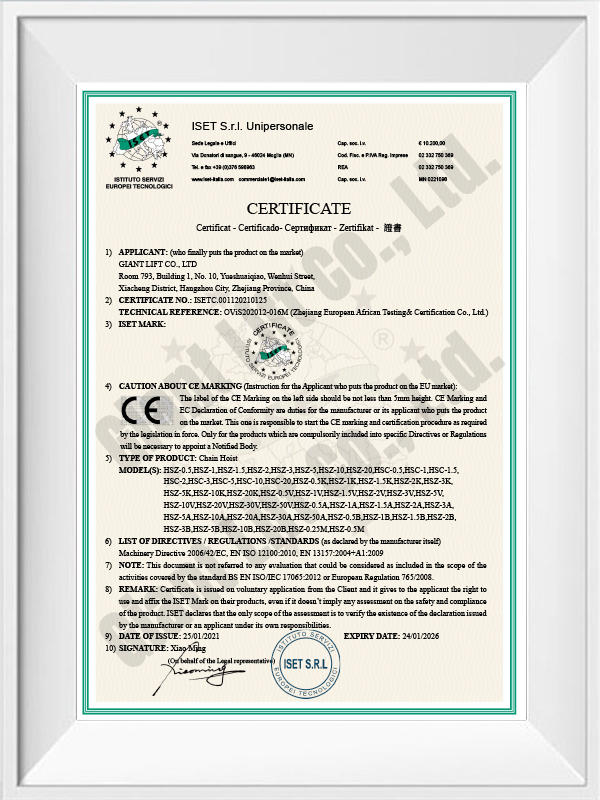

Weight indicators

The indicator defines the functionality of this scale system. Our indicators are specially designed for mobile use: Compact, shock and vibration proof and with lower power consumption. Digital calibration is available by using the buttons on the indicator. LCD display, Adjustable backlight.

Wireless Connection

Bluetooth

Power saving and strong comatibility

| Model |

|

RS-C20 |

RS-C20P |

RS-C30 |

RS-C30P |

RS-C50 |

RS-C5OP |

| Capacity |

kgs |

2000 |

2000 |

3000 |

3000 |

5000 |

5000 |

| Masuring range |

kgs |

1 |

1 |

|

|

2 |

2 |

| sensors |

aty |

2 |

2 |

2 |

2 |

2 |

2 |

| Max accuracy |

|

0.001 |

0.001 |

0.001 |

0.001 |

0.001 |

0.001 |

| Monitor |

|

LCD standard |

LCD with printer |

LCD standard |

LCD with printer |

LCD standard |

LCD with printer |

| ISO Class (Fork installation) |

|

ll |

ll |

lll |

lll |

lv |

lv |

| Ovarload prolecton |

% |

150 |

150 |

150 |

150 |

150 |

150 |

| Protection Class |

|

IP65 |

IP65 |

IP65 |

IP65 |

IP65 |

IP65 |

| Operating Temperature |

℃ |

-10 TO 60 |

-10 TO 60 |

-10 TO 60 |

-10 TO 60 |

-10 TO 60 |

-10 TO 60 |

Optional:

1. We can customize warehouse management system or match product with current management system according to customer' S requirements. Weight data can be uploaded in real time or stored and upload later.

2. Handheld unit with thermal printer available: For data logging, upload and printing.

English

English Español

Español