Here is more relevant industry knowledge about Material Handling

Material handling refers to the process of moving, storing, and controlling materials throughout the manufacturing, warehousing, distribution, consumption, and disposal stages. This process is critical to ensuring operational efficiency, reducing manual labor, improving safety, and maintaining a streamlined workflow. At Hangzhou Giant Lift Co., Ltd., we specialize in providing high-quality material handling equipment designed to make the transportation and movement of goods and materials safer, faster, and more efficient.

What is Material Handling?

Material handling involves a wide range of activities and equipment used to move materials from one point to another within a facility or across a supply chain. This includes lifting, loading, unloading, transporting, storing, and controlling goods and materials. The goal of material handling is to optimize workflows, minimize downtime, reduce accidents, and ensure that materials are available when needed.

There are various types of material handling systems depending on the specific needs of a facility, ranging from manual systems using basic tools, to more advanced automated systems incorporating conveyors, cranes, hoists, forklifts, and other specialized equipment.

Key Types of Material Handling Equipment

-

Lifting Equipment: This category includes electric hoists, manual hoists, lifting tables, and lifting cranes. These devices are used to raise, lower, and transport heavy materials within a facility. Electric hoists, for example, provide fast and reliable lifting capabilities for heavy loads, while lifting tables allow for easy positioning of materials at ergonomic heights.

-

Pallet Trucks: Manual and electric pallet trucks are designed to move palletized loads quickly and efficiently across short distances. Manual pallet trucks are operated by hand, while electric versions are powered, reducing operator effort and increasing speed.

-

Conveyors: Conveyor systems are used to transport materials continuously over fixed paths. They are commonly used in production lines, warehouses, and distribution centers to move goods, reduce manual labor, and improve efficiency.

-

Forklifts: Forklifts are one of the most commonly used material handling machines, designed to lift, transport, and stack materials. They come in various forms, including electric, gas-powered, and diesel-powered models, and are used in warehouses, construction sites, and manufacturing plants.

-

Cranes and Gantry Cranes: Cranes, including overhead cranes, gantry cranes, and jib cranes, are used to lift and move heavy or bulky items across large areas. Gantry cranes, in particular, are versatile and can be mounted on tracks or rails to allow for easy transportation of materials over long distances.

-

Trolleys and Carts: Used for moving goods over shorter distances, trolleys and carts are particularly effective in factories, warehouses, and distribution centers. These can range from simple hand carts to more sophisticated motorized models for larger loads.

-

Storage Systems: Effective material handling also involves efficient storage solutions such as shelving, racking systems, and automated storage and retrieval systems (AS/RS). These systems optimize space and help keep materials organized, improving overall warehouse management.

-

Lifting Chains & Lift Rings: These are essential tools for securely lifting and moving heavy loads. Lifting chains are strong, durable, and designed for heavy-duty applications, while lift rings provide reliable lifting points, ensuring secure attachment to the load.

Benefits of Efficient Material Handling

-

Increased Efficiency: Proper material handling systems and equipment help to streamline workflows by reducing the time spent on moving materials manually. By automating or simplifying the movement of goods, businesses can boost productivity and speed up the production process.

-

Reduced Labor Costs: Automated material handling solutions, such as electric hoists, conveyors, and automated storage systems, reduce the need for manual labor. This not only improves speed but also helps companies lower labor costs, particularly in tasks involving heavy lifting and repetitive motion.

-

Improved Safety: Material handling equipment like electric hoists and forklifts are designed to safely move heavy materials, reducing the risk of injury to workers. Proper material handling reduces the need for physical strain, and safety features such as overload protection and ergonomic designs further minimize workplace accidents.

-

Space Optimization: Efficient material handling systems also help optimize warehouse and facility space. By using conveyors, pallet trucks, and vertical lifting systems, businesses can better utilize available space, improving storage capacity and reducing clutter.

-

Better Inventory Control: Material handling systems can be integrated with inventory management systems to track goods as they move through a facility. This integration provides real-time data on inventory levels, ensuring better stock management, reducing shortages, and preventing overstocking.

-

Cost Savings: By optimizing workflows, reducing labor, improving safety, and enhancing space utilization, material handling systems help companies save costs. Automation and efficient material movement can lead to faster order fulfillment, fewer errors, and improved customer satisfaction.

Applications of Material Handling Systems

Material handling systems are used across a broad range of industries. Here are some common sectors where efficient material handling is essential:

-

Manufacturing: In manufacturing plants, material handling is crucial for moving raw materials, components, and finished products along the production line. Lifting equipment, forklifts, and conveyors help transport parts to assembly stations, manage inventory, and load/unload products from storage.

-

Warehousing and Distribution: In warehouses, material handling systems help move products from receiving docks to storage, and from storage to shipping areas. Conveyor belts, pallet trucks, and automated storage systems are frequently used in this environment to improve productivity and manage stock efficiently.

-

Construction: Material handling equipment like cranes, gantry cranes, and hoists are often used in construction sites to lift heavy building materials such as steel, concrete, and large machinery. These systems are essential for moving heavy loads safely and efficiently across job sites.

-

Retail and E-commerce: In retail warehouses and e-commerce fulfillment centers, material handling systems are used to manage the flow of inventory, pick orders, and prepare shipments for delivery. Automated systems, pallet trucks, and sorting conveyors are key in keeping operations running smoothly.

-

Shipping and Logistics: In shipping and logistics, material handling plays a critical role in moving cargo from ships, trucks, or trains to warehouses or distribution centers. Trolleys, forklifts, and cranes are often used to unload and transport goods across different transport modes.

-

Food and Beverage: Material handling systems are used in food processing and packaging plants to move raw ingredients, packaged goods, and finished products. Due to the nature of the industry, safety and hygiene are critical, and specialized equipment may be used to ensure compliance with industry regulations.

Why Choose Hangzhou Giant Lift Co., Ltd. for Your Material Handling Solutions?

-

Comprehensive Range of Products: At Hangzhou Giant Lift Co., Ltd., we offer a complete range of material handling equipment, including lifting equipment, pallet trucks, cranes, hoists, trolleys, and more. Whether you need simple manual equipment or fully automated lifting solutions, we have you covered.

-

Customization and Flexibility: We understand that every business has unique needs. Our material handling solutions can be customized to fit the specific requirements of your operations, whether you need specialized lifting equipment or unique storage systems.

-

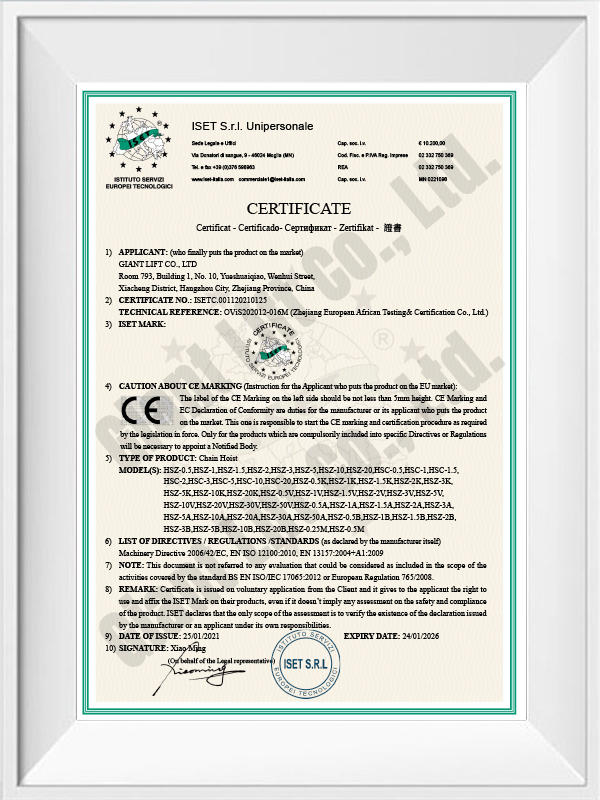

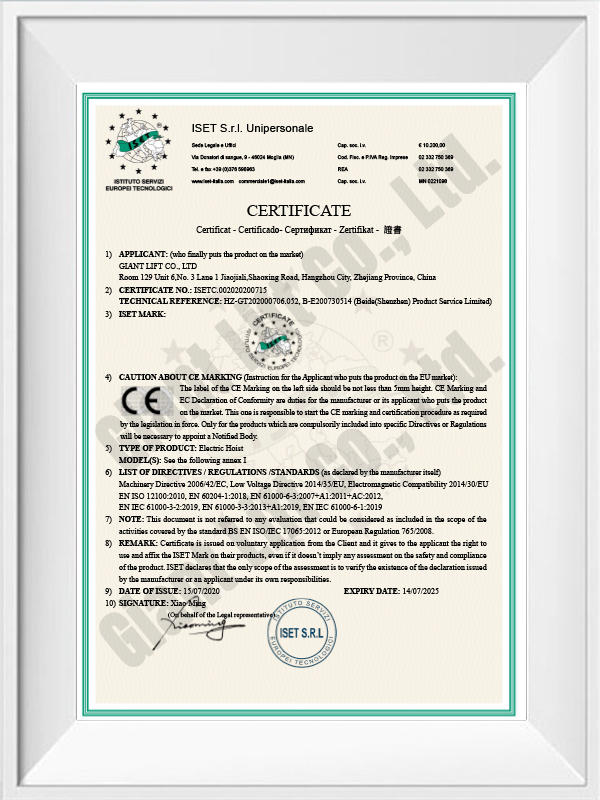

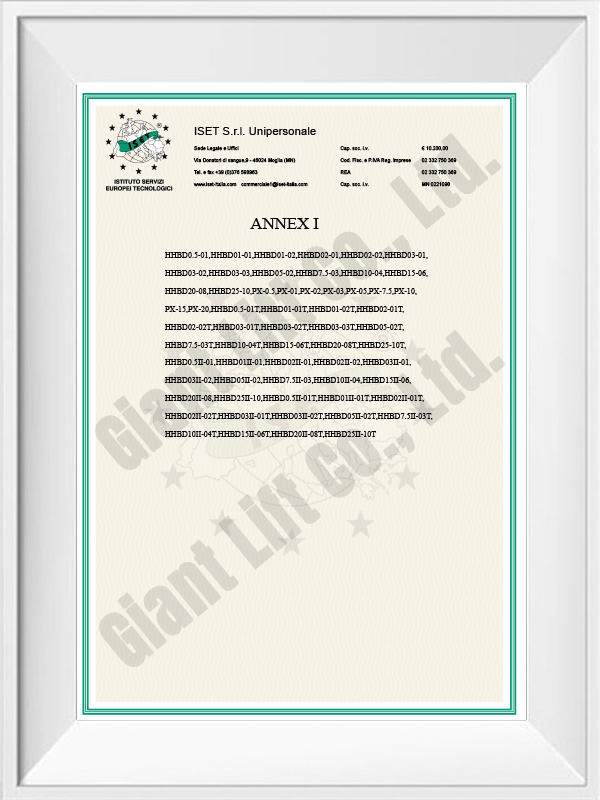

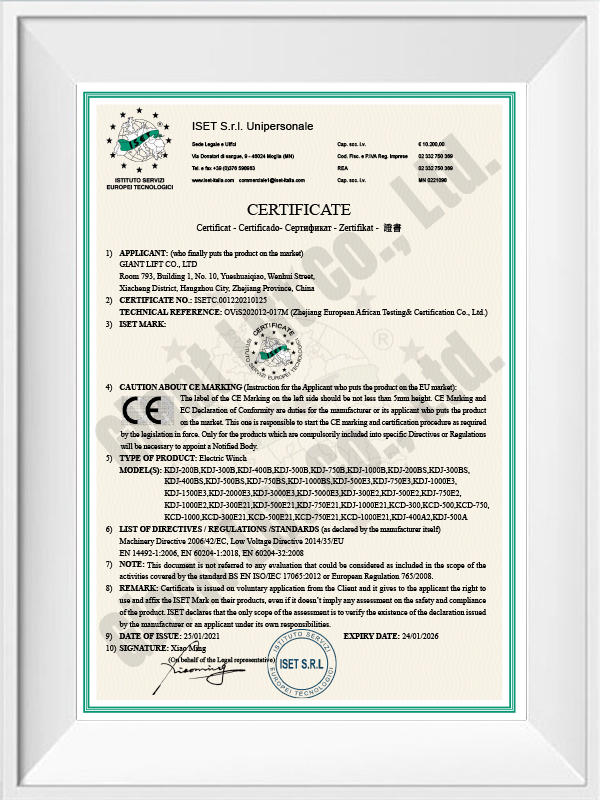

Industry Expertise: With over 35 years of experience in the lifting and material handling industry, Hangzhou Giant Lift Co., Ltd. is a trusted partner for businesses around the world. Our expertise ensures that we provide high-quality solutions that meet international standards.

-

Quality and Durability: Our products are built with high-quality materials and rigorous manufacturing processes to ensure long-lasting performance and reliability. We prioritize safety, durability, and ease of use in all our material handling solutions.

-

Global Reach: We supply material handling equipment to clients in over 50 countries worldwide. Whether you're in Asia, Europe, North America, or beyond, we offer tailored solutions that meet your specific material handling needs.

English

English Español

Español

.jpg?imageView2/2/format/jp2)