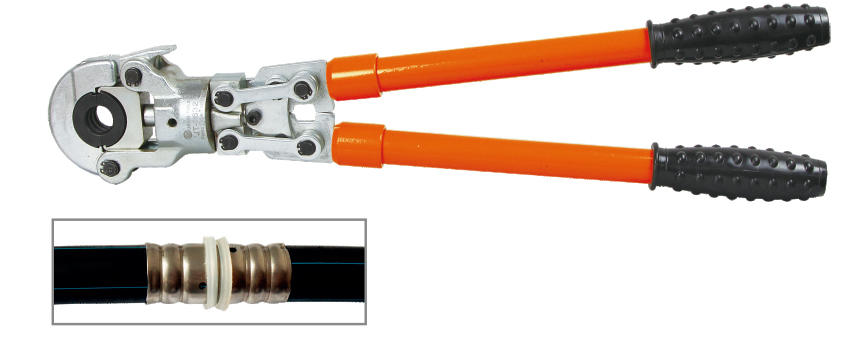

Here is more relevant industry knowledge about Hydraulic and Auto maintenance tools

In the world of automotive repair and maintenance, efficiency, safety, and precision are essential. Hydraulic and auto maintenance tools are indispensable for ensuring that vehicles and machinery are properly serviced, repaired, and maintained. From lifting heavy parts to precise repairs, these tools are designed to make automotive maintenance tasks quicker, safer, and more effective. Hangzhou Giant Lift Co., Ltd. offers a comprehensive range of hydraulic and auto maintenance tools that are trusted by professionals worldwide.

Hydraulic tools utilize hydraulic power to perform heavy lifting and other force-intensive operations. They are commonly used in industries where large amounts of force are needed to lift, press, or move objects. In the automotive sector, hydraulic tools are particularly useful for lifting vehicles, jacking up engines, or for tasks requiring precise pressure control.

Auto maintenance tools, on the other hand, include a broad range of hand tools, power tools, and specialized equipment used for vehicle repairs, servicing, and maintenance. These tools are designed for everything from tire changes to engine diagnostics and repairs. Together, hydraulic and auto maintenance tools form the backbone of any auto repair or maintenance facility, enabling technicians to perform a wide range of tasks efficiently and safely.

Hydraulic Tools for Automotive Maintenance

Hydraulic tools use the principles of fluid dynamics to generate force and perform heavy-duty tasks. These tools are essential for tasks that require the application of large amounts of force, which would otherwise be difficult or impossible to achieve manually. Some key hydraulic tools used in automotive maintenance include:

-

Hydraulic Jacks: Hydraulic jacks are used to lift vehicles or heavy machinery for inspection or repair. They are an essential tool in auto maintenance, allowing technicians to safely lift cars and trucks to access the undercarriage, tires, and other components. These jacks are highly efficient, requiring minimal effort to lift substantial weight.

-

Hydraulic Presses: A hydraulic press is used to apply controlled force for various automotive tasks, such as pressing bearings, bushings, or other components into place. It is also ideal for removing parts that are stuck or seized due to corrosion. Hydraulic presses provide uniform pressure and precision, making them indispensable in workshops that handle heavy-duty repairs.

-

Hydraulic Cylinders: Hydraulic cylinders are used to apply linear force, and they can be found in applications such as car lifting, wheel changing, and heavy-duty repairs. They are capable of generating a substantial amount of force in a compact form, making them ideal for auto repair shops where space and power are both important considerations.

-

Hydraulic Lifting Tables: Hydraulic lifting tables are used for lifting vehicles or engine parts to an ergonomic working height, minimizing physical strain on technicians. These tables are often used in auto repair shops for maintenance tasks such as wheel alignment or exhaust system repairs.

-

Hydraulic Torque Wrenches: These wrenches are used to tighten or loosen bolts with precision. By using hydraulic power, these tools can apply high torque without over-tightening, making them ideal for tasks that require exact torque settings, such as engine and suspension assembly.

Auto Maintenance Tools for Precision and Efficiency

Auto maintenance tools cover a wide range of devices, from hand tools to power tools, designed for specific repair and maintenance tasks. These tools are essential in performing routine maintenance, repairs, and upgrades to vehicles. Some of the most common auto maintenance tools include:

-

Impact Wrenches: Used primarily for tire changes, impact wrenches are powerful tools that quickly remove or install lug nuts. Available in both pneumatic and electric models, these tools are designed for high-torque applications, making them ideal for use in auto repair shops and tire service centers.

-

Pneumatic Tools: Pneumatic tools are powered by compressed air and are widely used in automotive repair. These tools include air drills, grinders, sanders, and polishers. Their lightweight design and high power make them excellent for tasks requiring fast and efficient work, such as sanding, grinding, and drilling.

-

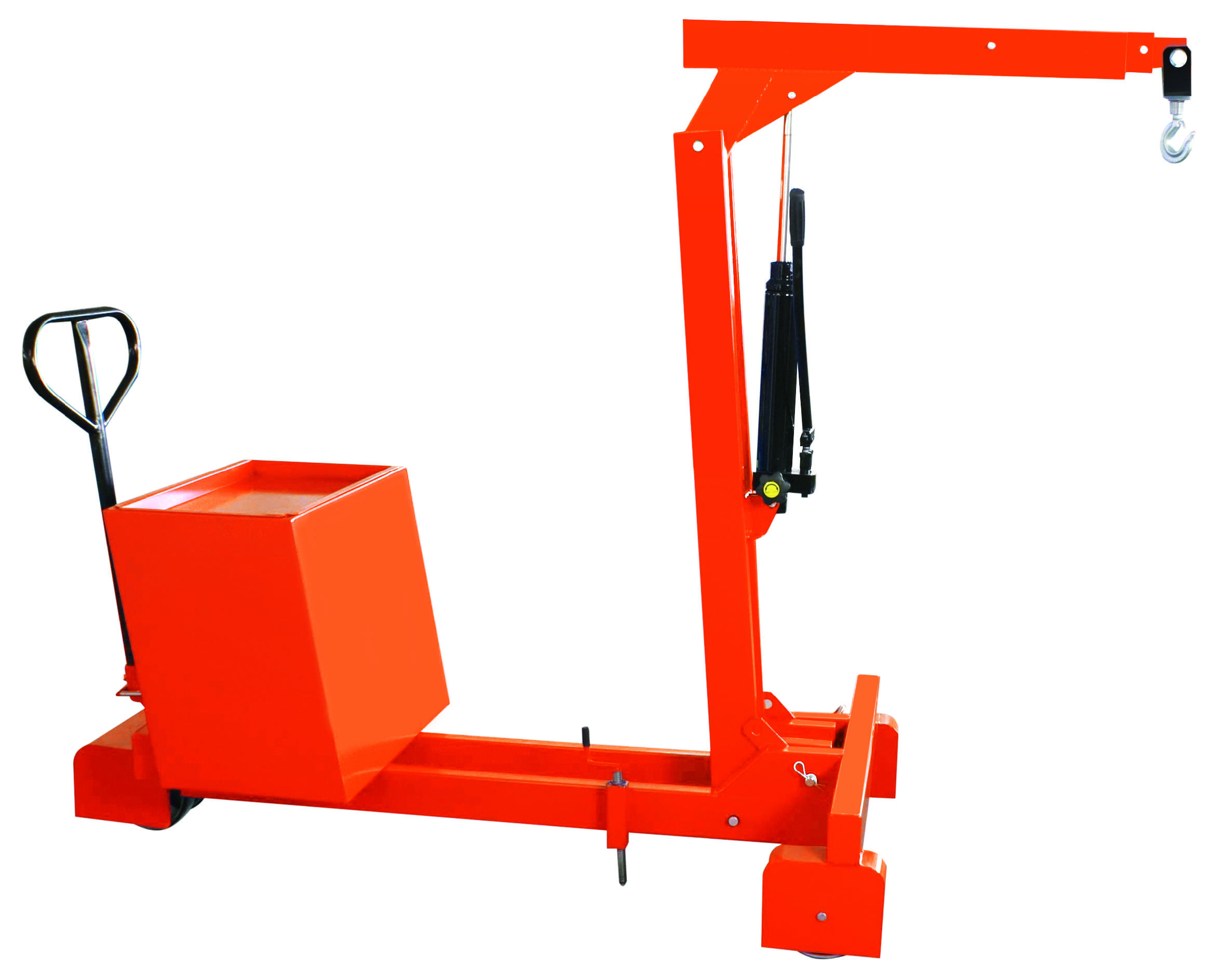

Automotive Lifts and Hoists: Auto lifts and hoists, both hydraulic and electric, are essential for raising vehicles so technicians can work underneath them. Hydraulic lifts are commonly used in auto repair shops for their precision and ability to handle heavy vehicles with ease. These tools can be installed as a permanent part of the workshop or as mobile units.

-

Diagnostic Tools: Modern vehicles come equipped with complex electronics, which require advanced diagnostic tools to troubleshoot problems. Auto maintenance professionals rely on diagnostic scanners to read error codes, assess engine performance, and identify issues with sensors or wiring.

-

Brake and Suspension Tools: Tools designed for brake and suspension system repairs are essential for ensuring the safety and performance of a vehicle. Brake bleeders, suspension spring compressors, and disc resurfacing tools are just a few examples of tools needed for this specialized area of auto maintenance.

-

Wrenches, Pliers, and Screwdrivers: Basic hand tools such as wrenches, pliers, and screwdrivers are still fundamental for auto repair. These tools are used for tasks such as tightening or loosening bolts, adjusting components, and making repairs in hard-to-reach spaces.

Why Hydraulic and Auto Maintenance Tools Are Essential for Automotive Repairs

-

Heavy-Duty Lifting and Handling: Hydraulic tools allow auto repair shops to lift, handle, and move heavy vehicle components with ease, which would otherwise require a large amount of manual labor or specialized lifting equipment. This reduces the risk of injury and improves workplace safety.

-

Precision and Efficiency: Hydraulic tools provide controlled, precise force, which is crucial for tasks that require exact pressure, such as pressing parts into place or tightening bolts to specific torque levels. This ensures that the job is done correctly, reducing the chances of mistakes or damage to components.

-

Increased Productivity: With hydraulic and other advanced auto maintenance tools, technicians can complete tasks faster and with less physical effort. This leads to greater efficiency in the repair process, allowing auto shops to handle more work and deliver faster service to customers.

-

Safety and Ergonomics: Many hydraulic tools are designed with ergonomics in mind, helping technicians work in a safer and more comfortable manner. For example, hydraulic lifts raise vehicles to a working height that minimizes the need for bending or kneeling, reducing the risk of back strain and other injuries.

-

Durability: Hydraulic tools, when properly maintained, are highly durable and capable of withstanding the stresses of heavy-duty applications. These tools are built to last and are designed to handle the high pressures and force required in the automotive repair industry.

Applications of Hydraulic and Auto Maintenance Tools

-

Vehicle Repair: Hydraulic jacks, presses, and lifts are used to lift vehicles, remove parts, and perform repairs on the undercarriage, tires, and suspension systems. These tools are critical for tasks such as tire changes, oil changes, and engine repairs.

-

Engine and Transmission Work: Hydraulic torque wrenches, presses, and lifts are used in engine assembly, disassembly, and transmission repairs. These tools ensure precision and reduce the physical strain on technicians while performing complex tasks.

-

Body Work and Collision Repair: For auto body shops, hydraulic pullers, jacks, and frames are essential for straightening bent or damaged vehicle frames. These tools are also used in collision repair to realign panels and reinforce body structures.

-

Truck and Heavy Equipment Maintenance: Larger vehicles, such as trucks and construction equipment, require specialized hydraulic tools for maintenance. Hydraulic lifting systems, jacks, and hoists are commonly used in these industries to lift and move heavy parts during repairs.

-

Automotive Assembly and Production: In manufacturing environments, hydraulic presses and lifts are used to assemble parts, install components, and move heavy materials through the production process. These tools are integral to high-volume production lines.

Why Choose Hangzhou Giant Lift Co., Ltd. for Your Hydraulic and Auto Maintenance Tool Needs?

-

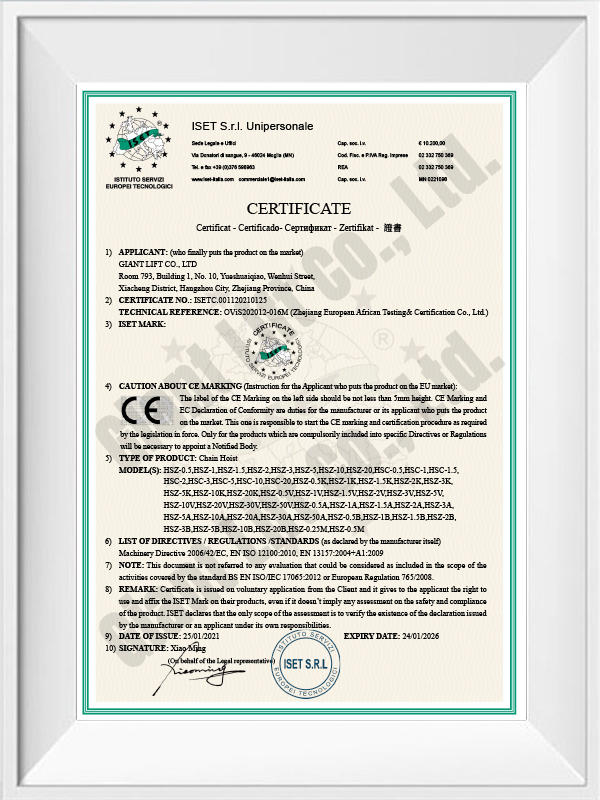

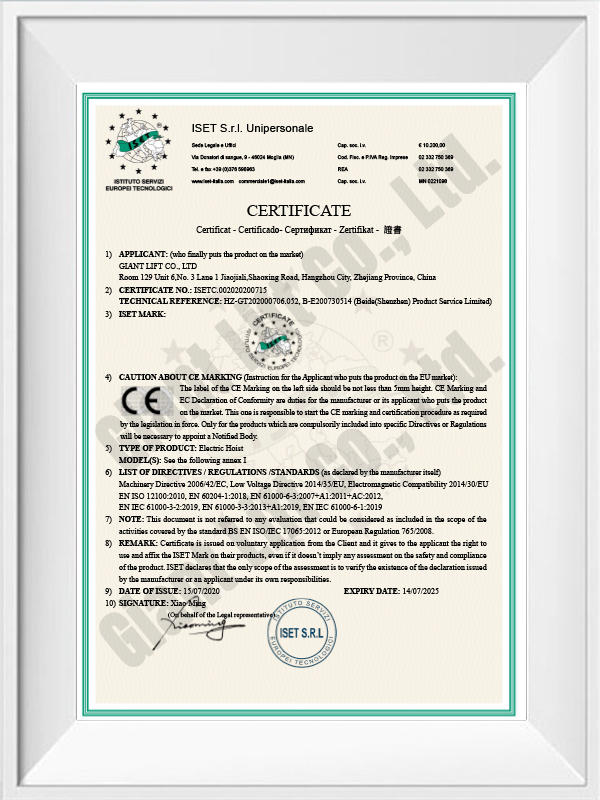

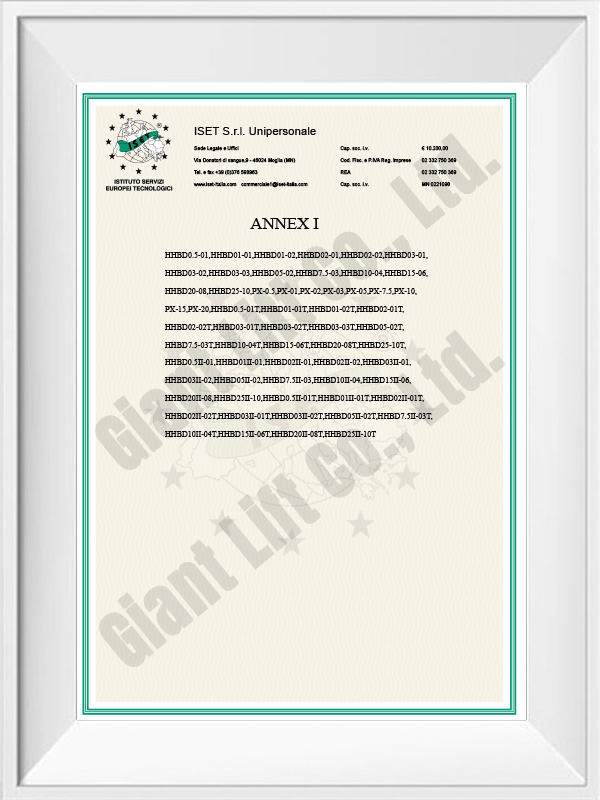

High-Quality Products: At Hangzhou Giant Lift Co., Ltd., we provide high-quality hydraulic and auto maintenance tools designed to withstand heavy-duty use. Our products are built for durability, precision, and safety, ensuring reliable performance across a wide range of automotive repair tasks.

-

Comprehensive Range of Tools: From hydraulic jacks and lifts to torque wrenches and pneumatic tools, we offer a full suite of solutions for all your auto maintenance needs. Whether you're operating a small repair shop or a large service center, our products can meet the demands of your operations.

-

Customization Options: We understand that different workshops have different needs. That's why we offer customizable hydraulic and auto maintenance tools tailored to your specific requirements, ensuring that you have the right tools for the job.

-

Safety and Ergonomics: Safety is paramount in the automotive repair industry. Our hydraulic tools are designed with built-in safety features, such as overload protection, and are ergonomically designed to reduce physical strain on technicians.

-

Global Reach: We have been supplying hydraulic and auto maintenance tools to customers in over 50 countries. No matter where you are, we are committed to delivering high-quality tools that meet international standards.

English

English Español

Español

.jpg?imageView2/2/format/jp2)